Do designers still use pencils or only digital input devices? Are labour-intensive, handmade clay models necessary? Are virtual reality experiences on the powerwall not much more impressive? The basic question is: What direction is the design process at Porsche developing in? Michael Mauer grins when he hears these questions once again. For the Vice President Style Porsche, there is no either-or:

“At Porsche there is no analogue versus digital, but rather analogue and digital. The two approaches complement each other and both have their advantages and disadvantages. It’s very significant that the interaction of these approaches is a definite success factor for our uncompromising design quality.”

A sketch with pen and paper remains the most important starting point for brainstorming in the car design area. For the next step, the design evaluation, physical models made of industrial plasticine – known in the business as clay – are still indispensable.

However, the iterative design process, which extends over many months, naturally also involves a digital representation of the models. Photorealistic simulations make it possible to investigate many alternatives, experiment with colours, and incorporate different surroundings during all phases of the process.

Porsche uses state-of-the-art tools that are also deployed in the fields of gaming and architecture. This high-end software is important, for instance, for the display and control concept in the interior, i.e. for the Porsche Driver Experience.

Virtual reality allows screen content and control concepts to be evaluated early, in many cases even before the first hardware components are available.

Mixed reality applications provide particularly immersive experiences. In the so-called modular VR seat model, relevant physical components such as the seat and steering wheel can be moved electromechanically to the appropriate vehicle position.

The design process at Style Porsche

1. First drawings: The design process always begins with sketches, often done conventionally with pen and paper. Almost simultaneously with the first drafts of the exterior, the interior is also sketched.

From these many drawings, Vice President Style Porsche Michael Mauer, and Peter Varga and Markus Auerbach, who are responsible for the exterior and interior design, select the most interesting ones.

2. 1:3 models: Up to ten clay models on a 1:3 scale are made in the course of the internal competition. The respective paired teams consisting of a designer and a modeller – the latter often a designer too, occasionally also a model builder – transform their first drafts into 3D models and optimise them. The most promising models are again selected.

While the designers still have relative freedom in the early phases of the process, measurements such as wheel size and wheelbase now become increasingly realistic.

3. 1:1 models: Industrial plasticine is used to build a scale model with all the details of a chosen draft on a frame of steel, wood and rigid foam. The modeller removes excess material, shapes edges and smooths surfaces. Tapes and films are also among the modeller’s resources.

These are used to emphasise important lines and contours, or to represent the surfaces of headlights and windows, for example. Some elements such wheels or logos are created with 3D printers and integrated into the clay model. It can take up to six months to complete a 1:1 model. Two life-sized models usually go head-to-head in the final of the internal design competition. These are given special silver-coloured films and painted.

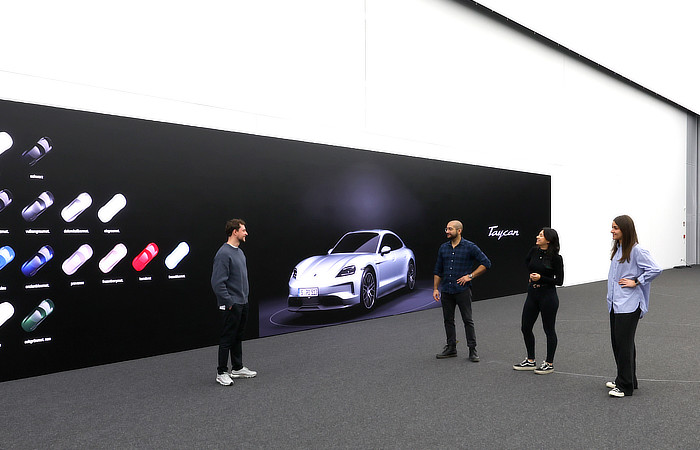

4. Virtual models: With all their surface data, details of the materials used (including paint and grain), screen content and product substance (for example, differences between the basic model and the Turbo), these models are complete representations of the future cars.

The doors and flaps can be opened, the light and shading varied with a mouse click.

5. Data control model: This model is created in parallel with the last steps of the design process along the path to the industrialisation. The so-called strak department is the interface with production, and it has the task of ensuring the construction feasibility down to details such as the headlights. Thus, the design freeze defines how the car will look, and the design release specifies how it will be produced.